Capabilities

K.BROS: Hellbent on Quality.

Overview

Making the impossible, possible.

Good enough will never apply to any project that ships out of our shop. We're craftsmen who follow the perfectionists mantra of Hellbent on Quality. And we have the modern fabrication machinery and technology to back our 'get it done right' grit. It's all made possible at K.Brothers Fabrication + Welding.

Our Capabilities

Design + Engineering + Prototyping

Making it right the first time doesn’t happen by chance. Perfection is an outcome the K.Brothers engineers and designers ensure as they work with you to transform your project concept into detailed CAD models. Once every specification is met, we then make it better as we optimize designs for functionality, manufacturability and cost-efficiency.

Our prototyping capabilities – featuring CNC machining, 3D printing, welding and sheet metal fabrication – takes what works in a design and puts it to the test in a real world environment. We do all this because we don’t look at it as just another project. Hardly. We’re here to build long term relationships.

Sheet Laser

By combining our brain power with the power of advanced fiber laser technology, we can provide unmatched speed and accuracy in cutting tight tolerances and complex geometries for a wide variety of materials such as mild steel, stainless steel and aluminum. Your project will have an exceptional edge quality and minimal heat distortion for everything from intricate architectural panels and custom enclosures to high-volume production parts, brackets and structural components.

- Machine: Amada 6kW Sheet Laser

- Surface area: 5'x10'

Tube Laser

If your project requires tube fabrication, K.BROS can handle a wide range of materials and profiles utilizing our high-powered tube laser technology. As perfectionist, we deliver clean, burr-free cuts with tight tolerances to reduce the need for secondary operations. This speeds up production to meet time sensitive deadlines for creating complex frames, custom enclosures, or handrails. From one-off prototypes to high-volume runs, we're proven for delivering consistent quality on every part. And we can do it faster, cleaner, and more cost-effective.

- Machine: Amada 3kW tube Laser

- Diameter: up to 6"

- Length: up to 235" (single piece)

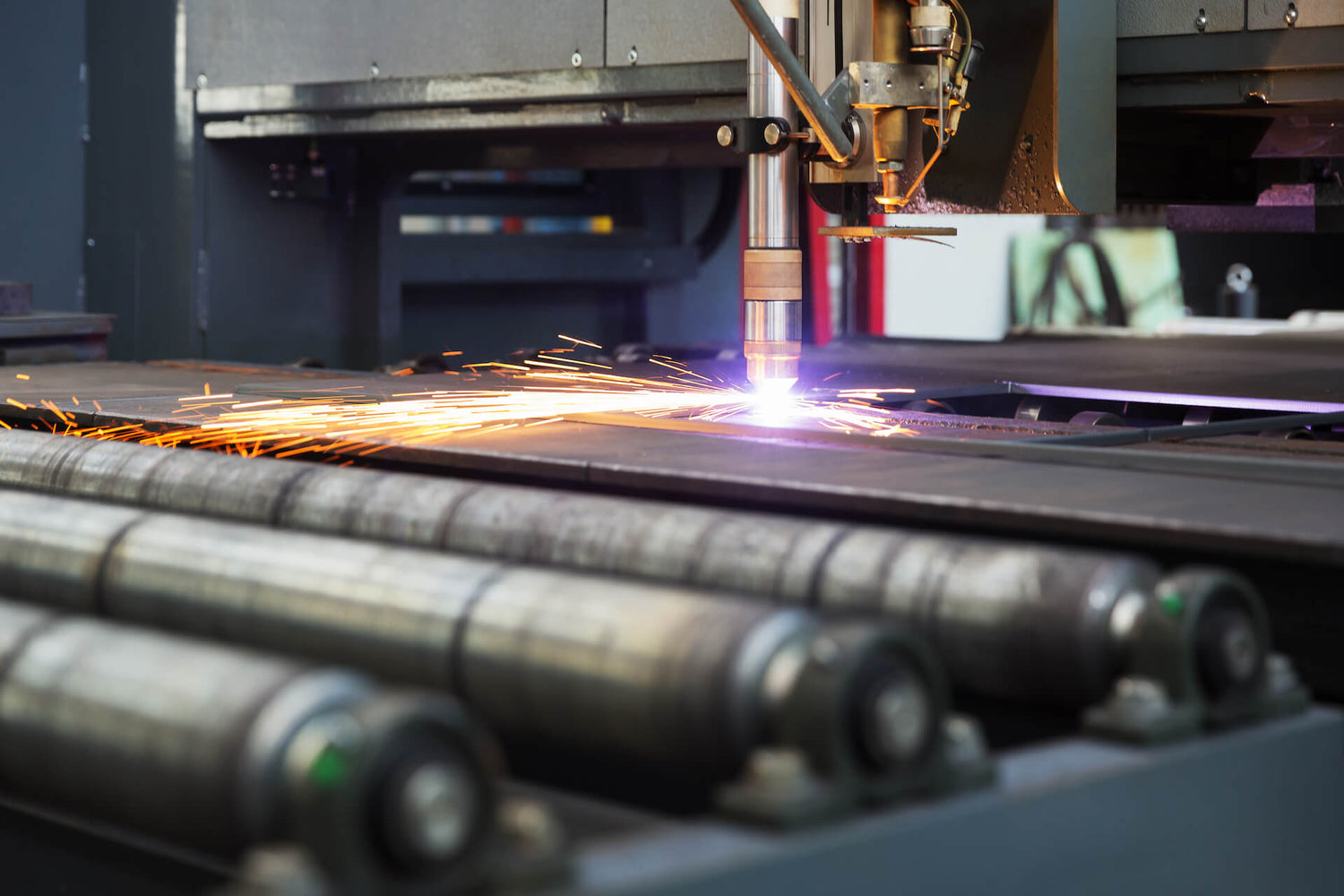

Plasma Cut

At K.Brothers we utilize plasma cutting for fabricating intricate shapes and patterns from sheets of mild steel, stainless steel and aluminum. Our fabricators use an advanced FlashCut CNC controller and 3D simulation to maximize material use and minimize waste for optimal outcomes for projects that include custom brackets and mounts, signage and lettering, equipment Parts, trailers and racks, fire pits, vehicle modifications and much more.

- Machine: Koike Shop Pro (Sheet + Tube)

- Surface area: 5'x10'

Precision Forming

Our press brake machines enable K.BROS to handle everything from delicate precision work to high-force forming of heavy metal stock. The Amada excels in high-precision bending of complex parts, allowing for tight tolerances and intricate geometries across a range of materials. In contrast, the Verson offers heavy-duty forming capabilities suited for thicker materials and larger parts. It's a workhorse for structural components, heavy gauge brackets, frames and industrial panels.

- Machine: Amada 90 ton 8 axis press brake

- Surface area: 8ft

- Machine: Verson 155 ton press brake

- Surface area: 12ft

Saw Cut

We have the capabilities to saw cut metal stock bars, tubes, angles, or sheets to achieve a straight, clean edge at a specific length or angle. These are high precision cuts with minimal burrs and are an essential preparatory step before welding, machining, or assembly.

- Round: up to 8.5"

- Rectangular: up to 5"x10"

Welding

The comprehensive welding services at K.BROS covers industrial, commercial, and custom fabrication. Our certified welders are experienced in multiple welding processes to ensure the highest quality and precision for heavy-duty structural applications, tight-tolerances and overlapping materials. We maintain industry standards (AWS, ASME, or customer-specific requirements), with welds inspected for structural integrity and finish quality. The final product is versatile, durable and effective in outdoor or harsh environments.

• MIG, TIG, Stick, Remote and Shear Welding

Finishing

Our fabrication finishing expertise is applied to metal surfaces after they are shaped and assembled to improve appearance, durability, corrosion resistance and functionality. It's the finishing touch that helps take your project beyond expectations.

- Grinding

- Powder Coating

- Painting

Your custom build starts here.

There are countless fabrication shops. Discover why there's only one like K.Brothers Fabrication + Welding for projects built with a 'can do' attitude.